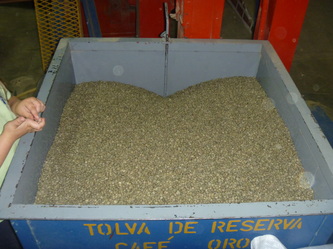

The machine begins with a huge silo where we empty our bags of green beans; They then make their way down metal tubes where a man with a hammer kept banging to make sure they went on their merry way; Then there were several shoots where the large beans are separated; Lastly they make their way onto a machine like a shaking pool table with three shoots for the different densities of coffee where a man inspected periodically to make sure the shoots were set at the right angles; Then the coffee was bagged with a sewing machine.

Very pleased 700+lbs of high quality coffee with negligible defects and about 20-30lbs of basically low quality either rather large, rather small or damaged beans with defects. We will only use the high quality which is now back on the farm resting for 90 days before roasting. Next step - cupping it in February.

RSS Feed

RSS Feed